Our Products

Fluid-Quip offers a Full Line of Equipment for all Wet Mill needs:

Disc Mills

Disc Nozzle Centrifuges

Filtration Centrifuges

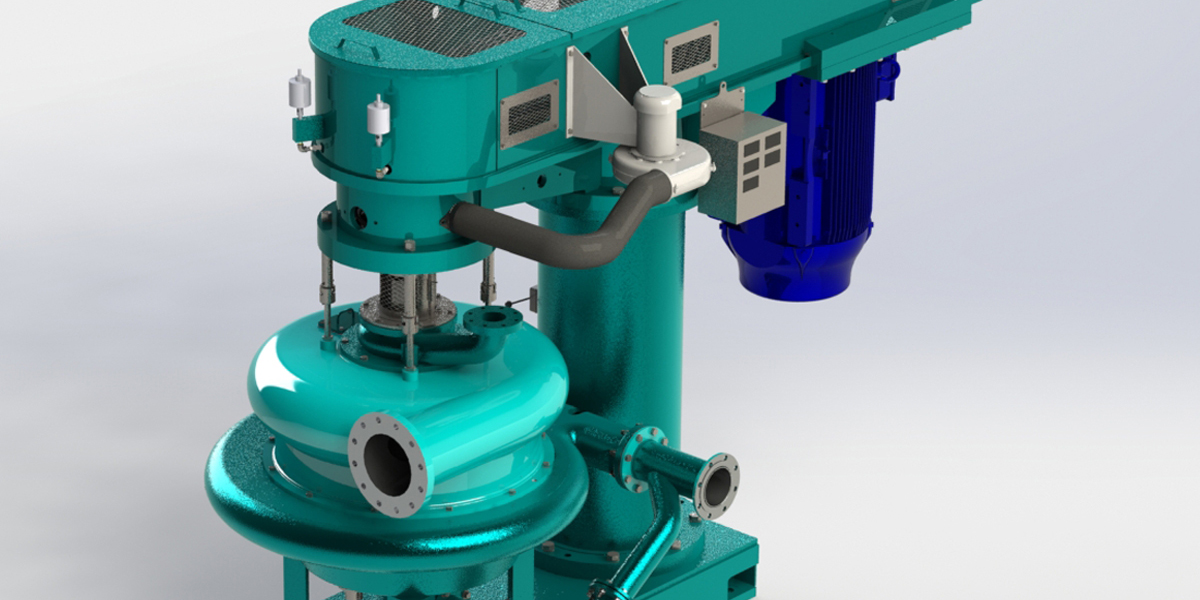

The Fluid-Quip Filtration Centrifuges offer a new innovative approach to liquid solids separation technology. The filtration centrifuges have internal washing stages to provide efficient counter current displacement washing inside the machine.

This new technology is the cornerstone of the Maximized Stillage Co-Products System available for recovering protein from whole stillage in dry grind ethanol plants.

The Filtration Centrifuge also offers an alternative to pressure screens for corn wet milling fiber washing and dewatering applications

Germ Separation

Gravity Screens

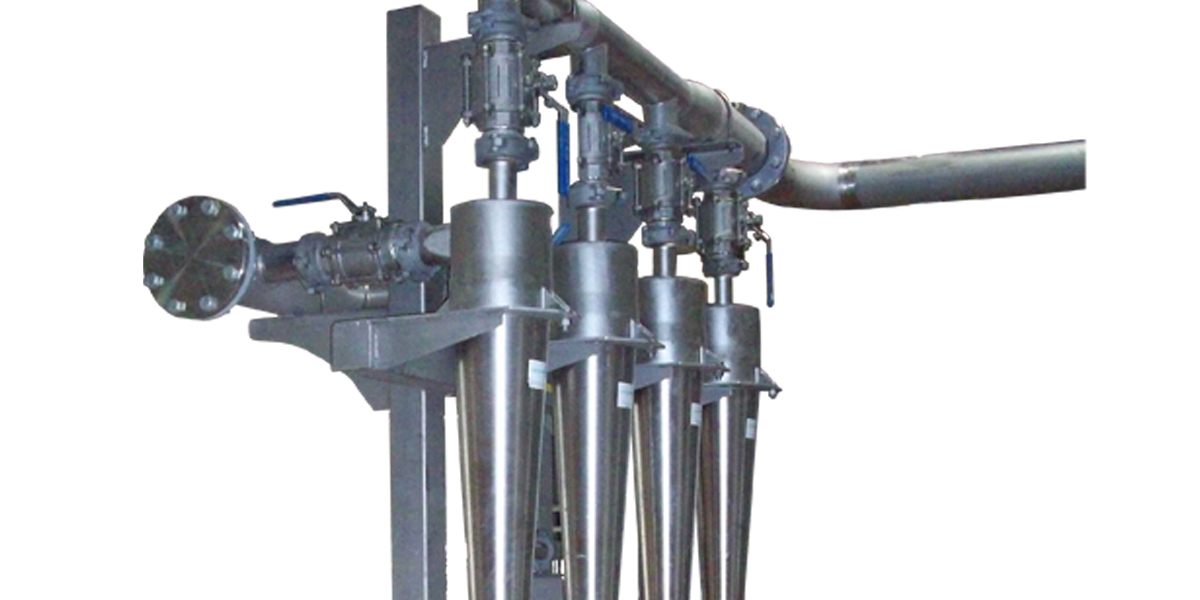

Grit Removal

Fluid-Quip offers grit removal systems and cyclones in various configurations. Efficient and properly sized grit cyclone systems protect downstream machines for foreign object damage and wear from grit. All grit removal cyclone systems are customizable to fit specific capacities and particle size filtration needs. Fluid-Quip manufactures 8”, 6”, and 3” grit removal cyclones.

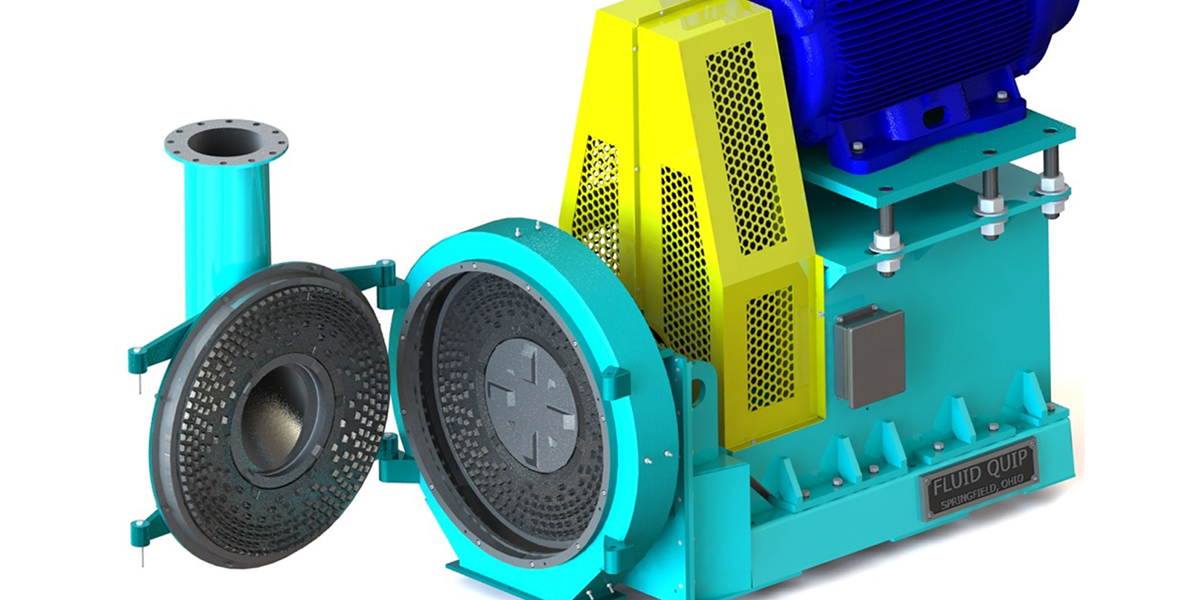

Impact Mills

Fluid-Quip offers the FQ-IM40 and FQ-IM40H horizontal rotor Impact Mills for the corn wet milling third grind application. By combining gentle action on the delicate corn fibers with powerful crushing power on the bound starch particles, the Fluid-Quip Impact Mills do make quite an Impact on corn wet mill bound starch numbers and overall starch yields.

Paddle Screens

Fluid-Quip’s Paddle Screens are high capacity dewatering screens used to separate solids from liquids, or refine solids by separating according to particle size. In the corn wet milling industry, the paddle screen suite offer by Fluid-Quip is an alternative to pressure screens for fiber washing, fiber dewatering, and germ washing applications.

Pressure Screens

Fluid-Quip pressure screens are designed for efficiency and simplicity in liquid-solid separation of fibrous non-abrasive materials and for ease of operation, to simplify maintenance and to reduce down time. These Fluid-Quip 120° Pressure Screens consists of a cabinet with a specified number of compartments, each enclosing a single screen, supplied by three to five (3-5) nozzles connected to a feed header.

Rotary Strainers

The Fluid-Quip Rotary Strainer is a separation device designed for continuous delivery of a strained liquid or slurry stream, free of oversize particles. With a Fluid-Quip rotary strainer installed ahead of your process equipment, you can rest assured knowing that your process is protected against contamination, and your process equipment is protected against plugging, excessive wear, or failure due to contamination. Our improved design allows for consistent operation and minimal maintenance.

Starch Washing Systems

Starch washing consists of separating starch particles from soluble and insoluble proteins. Fluid-Quip’s Radial matrix starch washing units contain a variable number of cyclonettes (small cyclones) that function as centrifugal separation devices. Cyclonettes are mounted between two concentric stainless-steel cylinder cartridges that form three separate chambers including, feed slurry, underflow stream, and overflow stream.