Filtration Centrifuges

The Fluid-Quip Filtration Centrifuges offer a new innovative approach to liquid solids separation technology. The filtration centrifuges have internal washing stages to provide efficient counter current displacement washing inside the machine.

This new technology is the cornerstone of the Maximized Stillage Co-Products System available for recovering protein from whole stillage in dry grind ethanol plants.

The Filtration Centrifuge also offers an alternative to pressure screens for corn wet milling fiber washing and dewatering applications.

FQ-FC3000

DESIGN FEATURES

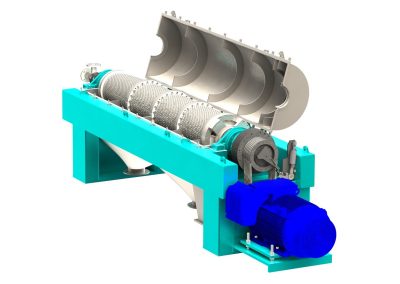

- The FC3000 is a horizontal, cylindrical centrifuge designed for heavy-duty, continuous operation in washing, filtering and separating of fiber or other solids.

- Customizable machine configuration with 0-4 countercurrent washing steps

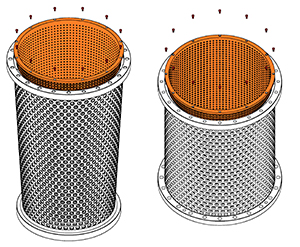

- Cylindrical screen bowl design uses slotted screens and can vary slot size at each stage

- Total screen area of 4.7 M2 with 1000 G at bowl wall

- Motor and conveyor speed controlled by PLC to maintain constant cake moisture

Specification

- Maximum capacity of 80 m3/hr. of suspension input and 20 m3/hr. of solids output per hour.

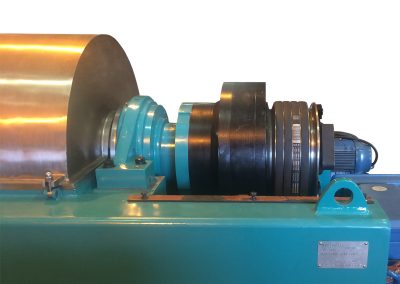

- Maximum of 268 horsepower (200 kW), the centrifuge can operate at up to 1500 rpm; however, the preferred maximum working speed is 1200 rpm. Protection against mechanical overload is provided by a mechanical torque limiter on screw conveyor shaft.

For more information,

contact us today.

FQ-FC3000 filtration centrifuge

The FQ-FC3000 centrifuges offers three internal washing stages and special dewatering section to ensure maximum cake dryness at the discharge.

FQ-FC2000 filtration centrifuge

The first generation fiber filtration centrifuge offers two internal washing stages for lower capacity applications or applications that require minimal washing.

FQ-FC3000

The FQ-FC3000 Filtration Centrifuge is the latest generation of a new machine design (Patented) for fiber washing and de-watering processes in solids extraction applications such as crystals or fibers.

The FQ-FC3000 features maximal centrifugal separation with internal counter-current washing stages.

The FQ-FC3000 is a horizontal, cylindrical centrifuge designed for heavy-duty, continuous operation in washing, filtering and separating of fiber or other solids and has a maximum capacity of 80 m3/hr. of suspension input and 20 m3/hr. of solids output per hour.

Designed to be driven by a maximum of 268 horsepower (200 kW), the centrifuge can operate at up to 1500 rpm; however, the preferred maximum working speed is 1200 rpm. Protection against mechanical overload is provided by a mechanical torque limiter on screw conveyor shaft.