Awesome product

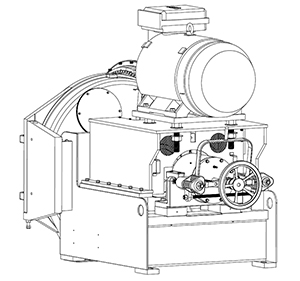

Fluid-Quip’s Disc Mills are designed for optimum performance. Our engineers focused on durability, structural stability and solidifying tram control to minimize vibration, reduce wear and maintenance costs. The result is one of the finest wet corn disc mills in the world today. We have three different models of our single disc mills: 124, 136 and 152.

FQ-124 • FQ-136 • FQ-140 • FQ-152A/E • FQ-152B • 494 Retrofit • FQ-236 • FQ-252

DESIGN FEATURES

- Heavy construction and a rigid refiner case maintain a better tram resulting in less vibration, longer bearing life and lower maintenance cost.

- Heavy duty motor supports

- ??? inch thick motor mounting plate

- ??? inch diameter motor mounting rods

- All process contact parts are 316 stainless steel, protecting against corrosion and extending operating life

- Hand wheel adjustment easily sets the rotating disc position accurately to control grinding plate gap within 1/1000 of an inch

- Split Bearing Housing Design (52″ machine)

The quick release mechanism on the 36″ single disc mill combines precise control of plate gap with benefit of ability to quickly back off the discs and return to preset operating gap.

SPECIFICATIONS

- 316 stainless steel process contact parts

- 1,800 RPM maximum speed

- Grease lubricated bearings (24″ and 36″ machines)

- Gravity feed

- Hinged door swings both ways for easy plate change

- Manual disc position adjustment

For more information,

contact us today.

Product 1 v1

The FQ-124 Single Disc Mill is a designed for optimum tram alignment, minimal vibration, and lasting durability in high capacity heavy-duty operation of the 1st grind stage (8,000 bushels/day [200 MTPD]) and 2nd grind stage (16,000 bushels/day [400 MTPD]) of the wet corn grinding process. Designed to be driven by a maximum of 75 horsepower (56 kW), the mill can operate at up to 1800 rpm.

FQ-136

The FQ-136 36″ single revolving disc grind mill is designed for high capacity, heavy-duty operation for Fluid-Quips Select Grind Technology (SGT) ethanol process. Designed for attachment to a maximum of 300 horsepower (224 kW), the mill can operate up to 1800 RPM. Bearings are grease lubricated and do not require additional grease except during scheduled maintenance.

FQ-140

The FQ-140E Single Disc Grind Mill cab be supplied with Automatic Plate Gap Adjuster components (servo motor, gear reducer, positive stop), Inpro Seal bearing isolator, integrated lubrication system tank, coupling for 500 HP motor, DIN flange for inlet, and standard alloy grinding plates.

The FQ-140E is a 40” direct driven, single revolving disc mill designed for Fluid-Quip’s SGT Ethanol Process. Designed to be driven by a maximum of 500 horsepower (343 kW), the mill can operate at up to 1800 rpm. An automatically controlled lubricating system is integrated into the mill base to distribute cooled, circulating oil evenly and constantly to tapered roller bearings.

FQ-152A/E

The FQ-152E is a 52” single revolving disc mill designed for high capacity heavy-duty operation in 1st, 2nd or 3rd stage of the wet corn grinding process. Designed to be driven by a maximum of 1000 horsepower (746 kW), the mill can operate at up to 1800 rpm. An automatically controlled lubricating system is integrated into the mill base to distribute cooled, circulating oil evenly and constantly to tapered roller bearings.

FQ-152B

The 152B, 52” single revolving disc mill is designed for high capacity, heavy-duty, first and second grind operations at up to 900 rpm, driven through a belt drive system by a maximum of 350 horsepower (261 kw). Bearings are grease lubricated and do not require additional grease except during annual maintenance.

494 Retrofit

This machine offers the same performance and dependability of fluid quips new machines using the frame of the old machine and keeping the foot print the same. This reduces piping and mounting costs and may reduce manufacturing costs as well. Once rebuilt the new machine will accept all of Fluid-Quips replacement parts to lower cost of maintenance and increase dependability.

494-52 is a retrofitted 494, remanufactured to fluid quips standards, and cutting-edge production. The main Quill assembly and other various parts are interchangeable with other Fluid-Quip products and are still currently manufactured.

The 494-52 is a direct driven single 52”-disc grind mill with freestanding coupled motor designed for high capacity heavy-duty operation with optimum tram alignment, minimal vibration and lasting durability and to be driven by a maximum of 1000 horsepower (746 kW) at up to 1800 rpm. This machine can be fitted with a quick release assembly or auto adjust technology.

FQ-236

The FQ-236 Double Disc Mill is designed for optimum tram alignment, minimal vibration, and lasting durability. The mill has two 36” counter-rotating discs that can operate at up to 1800 rpm, each driven by a maximum of 250 attached horsepower (186 kW) through belt drive systems with extra heavy motor supports.

The FQ-236 mill features a feed end and a control end. The control end can be fitted with a quick release assembly or auto adjust technology.

FQ-252

NEED COPY…Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.