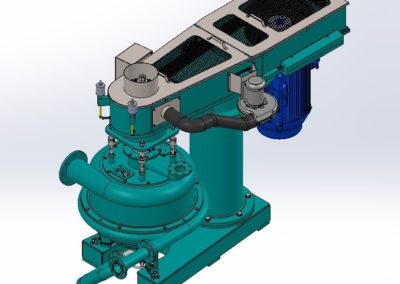

Disc Nozzle Centrifuges

Fluid-Quip has combined many maintenance friendly features with proven separation technology to design a Disc Nozzle Centrifuge that operates with reliable efficiency and minimum downtime. No other Disc Nozzle Centrifuge on the market can compare, feature to feature.

FQC-800 • FQC-800T • FQC-800E • FQC-950 • FQC-950T • FQC-950E

DESIGN FEATURES

- Heavy Duty construction minimizes vibration and ensures structural stability. All outer housing components constructed of 316 stainless steel. The bowl, hub, and cover are made of Ferallium.

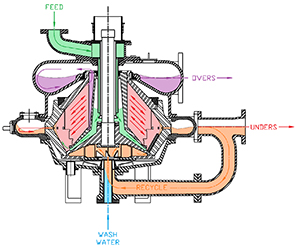

- Straight forward nozzle installation using a unique nozzle and tool system (Patent #6,216,959). Fluid-Quip’s unique nozzle tool enables nozzle installation, and removal through opening of underflow volute.

- Patented nozzles have an improved carbide insert flow passage and a unique removal slot that allows our removal tool to grab on to the nozzle for installation and removal.

- Inspection port in underflow volute allows nozzles to be inspected and replaced without raising the bowl or removing housing.

- Slide mounted motor supports work with an adjustment screw to quickly adjust belt tension.

- Improved lock ring design allows for consistent, simple, and safe removal, time after time.

- Local panels are offered for monitoring both bearing temperatures, vibration, lubrication rate, and RPM

- Wash water injected directly into bowl to allow for increased wash rates and improved washing efficiency.

- Many internal rotating components interchangeable with existing models.

- Disc Nozzle Centrifuges can be tailored to each unique operation: Primary Service, Gluten Thickening, Mill Stream Thickening, or Clarifying

SPECIFICATIONS

- Ferallium 255 Bowl, hub, and cover. All other process contact parts, including housing made of 316 stainless steel.

- Carbon Steel base, column, and radial arm.

- Oil drip bearing lubrication system (oil recirculation system available)

- Vibration monitor and bearing temperature monitor

- Built in hydraulic hoist actuated by external hydraulic power system

CENTRIFUGE EXPERTISE

Count on Fluid-Quip to be there for you anytime that assistance is needed with a new or existing centrifuge. Our design, process, and maintenance experts are available to assist from our office or at your plant for emergency problems, routine maintenance, process optimization, or operator / maintenance training.

Our expert service team can also provide all your rebuild needs for existing machines, including complete machine restorations, conversions, and bowl repairs, for any machine, regardless of the make or model.

For more information,

contact us today.

FQC-950 Primary Centrifuge

The FQC-950 Centrifuge offers the highest capacity for Fluid-Quip Disc Nozzle Centrifuges. The centrifuge can handle 40,000 BPD (1000 MTPD) of equivalent grind rate in Primary and Gluten Thickening operation.

FQC-800 Centrifuge

The FQC-800 Centrifuge offers the highest capacity for Fluid-Quip Disc Nozzle Centrifuges. The centrifuge can handle 20,000 BPD (500 MTPD) of equivalent grind rate in Primary and Gluten Thickening operation.

FQC-800, FQC-800T, FQC-800E

Straight forward nozzle installation using a unique nozzle and tool system (Patent #6,216,959). Fluid-Quip’s unique nozzle tool enable s nozzle installation, and removal through opening of underflow volute. Fluid-Quip uses a patented Nozzle design (Patent #6,511,005) with improved flow passages along with increased wear protection. Bowl, hub and cover are made with a duplex alloy Ferralium 255 with high strength and superior wear resistance. Local panels are offered for monitoring both bearing temperatures, vibration, lubrication rate, and RPM. A 4-20 mA signal can be relayed to the central controller. The adjustable lubrication system provides optimum lubrication while reducing operating temperature. Oil is provided to the system by drip and is monitored by a fiber optic sensor. The drip rate is displayed on a local panel, and a 4-20 mA signal is relayed to the central controller.

Fluid-Quip offers a 30” MST and Clarifier with grind rate capacities up to 40,000 BPD (1000 MTPD). Fluid-Quip’s 30” Primary with grind rate capacities up to 20,000BPD (500 MTPD). Fluid-Quip’s 30” GT with grind rate capacities up to 20,000 BPD (500 MTPD).

FQC-950, FQC-950T, FQC-950E

Straight forward nozzle installation using a unique nozzle and tool system (Patent #6,216,959). Fluid-Quip’s unique nozzle tool enable s nozzle installation, and removal through opening of underflow volute. Fluid-Quip uses a patented Nozzle design (Patent #6,511,005) with improved flow passages along with increased wear protection. Bowl, hub and cover are made with a duplex alloy Ferralium 255 with high strength and superior wear resistance. Local panels are offered for monitoring both bearing temperatures, vibration, lubrication rate, and RPM. A 4-20 mA signal can be relayed to the central controller. The adjustable lubrication system provides optimum lubrication while reducing operating temperature. Oil is provided to the system by drip and is monitored by a fiber optic sensor. The drip rate is displayed on a local panel, and a 4-20 mA signal is relayed to the central controller.

Fluid-Quip offers a 36” MST and Clarifier with grind rate capacities up to 80,000 BPD (2000 MTPD). Fluid-Quip’s 36” Primary with grind rate capacities up to 50,000 BPD (1250 MTPD) with proper configuration. Fluid-Quip 36” GT with Grind Rate capacities up to 40,000 BPD (1000 MTPD).