Gravity Screens

Fluid-Quip Gravity Screens are designed for ease of operation and for simplicity of maintenance to reduce down-time in liquid-solid separation and de-watering applications such as wet corn milling, pulp and paper processing, chemical polymers, waste water treatment and food processing.

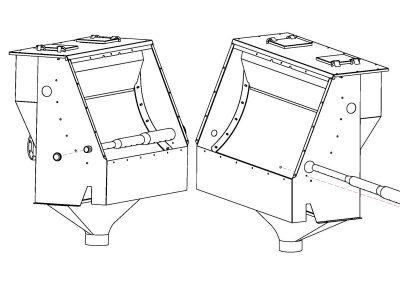

The Fluid-Quip Gravity Screen consists of a cabinet enclosing separator screens. Slurry pumped, or gravity fed into the head box overflows the weir and accelerates down the screen surfaces where it adheres to the screen bars. Solids larger than the Gravity Screen openings are retained on the surface while finer slurry passes through the screen openings. With free drainage material, most free fluid is removed in one pass. The retained larger solids roll down off the screen for re-use or disposal.

The screen is constructed of 316 stainless steel and contains no moving parts. The built in tapered headbox and an 18-gauge stainless steel flow baffle ensures steady even flow over the weir and across the screen surface. Sturdy hinged 24-gauge stainless steel doors include vapor tight seals to limit vapor emissions from the box. The screen surface is included and installed per customer specification.

Fluid-Quip Gravity Screens with 31” long screens and 1mm screen spacing are common for germ washing applications. Germ washing screens are designed special to accommodate wash headers and are stackable so the product can cascade from one screen to the next without the need for pumps in between stages.

Fluid-Quip gravity screens with 54” long screen surfaces and 3mm slot openings are commonly used for dewatering before 1st Grind. Screens are available in many sizes, ranging from 2 feet wide to 10 feet wide, with grind capacities up to 100,000 bpd per screen (2500 MTPD).

Fluid-Quip gravity screens with 54” long screen surface and 1.5 mm slot openings are commonly used for 2nd grind dewatering. Screens are available in many sizes, ranging from 2 feet wide to 10 feet wide, with second grind dewatering capacities up to 100,000 bpd per screen (2500 MTPD).

For alternate dewatering technologies, please visit the pages on Paddle Screens or Pressure Screens.

Fluid-Quip can assist customers in determining the configuration of screen sizes and openings that best fill their production requirements and budget.

Common Screen Configurations

GS-2-31 • GS-2-54 • GS-4-31 • GS-4-54 • GS-6-31 • GS-6-54 • GS-8-54 • GS-10-54